Anneleen, onze eerste 100% elektrisch rijdende collega

september 3, 2022

Teambuilding: karting

september 30, 2022A few weeks back the new and final version of Eudralex Volume 4 Annex 1 “Manufacture of Sterile Medicinal Products” was published on the website of the European Commission. This new version will come into operation on 25 August 2023, except for point 8.123 which is postponed until 25 August 2024.

Where the current version of Eudralex Volume 4 Annex 1 is 16 pages, the new version has no less than 59 pages. The new EU annex 1 regulation provides a lot more detail, technical requirements and some entirely new chapters.

This blog article gives an overview of the most important changes and new content in Eudralex Annex 1. If you or company needs advice, guidance on implementing the new requirements then do not hesitate to contact us.

The new version has 10 chapters

- Scope

- Principle

- Pharmaceutical Quality System (PQS)

- Premises

- Equipment

- Utilities

- Personnel

- Production and specific technologies

- Environmental and process monitoring

- Quality control

I will not go as far as saying that the new Eudralex Annex 1 reads like a thriller, but at least it is structured like a proper book and the additional level of detail make it a welcome addition in the landscape of regulatory guidance on aseptic manufacturing.

Below I will provide my insights after a first, in depth reading of the new Eudralex Annex 1 highlighting the most important changes and additions.

Chapter 1 / Scope

This introductory section contains some important statements such as:

Where specific limits or frequencies or ranges are specified, these should be considered as a minimum requirement.

The statement above is new as the previous version of Eudralex Annex 1 often stated “guidance values”.

Some of the principles and guidance, such as contamination control strategy, design of premises, cleanroom classification, qualification, validation, monitoring and personnel gowning, may be used to support the manufacture of other products that are not intended to be sterile.

Which confirms current practice in the industry that Eudralex Volume 4 Annex 1 is not only applied to sterile product facilities.

Chapter 2 / Principle

Highlights the importance of Quality Risk Management (QRM), introduces the term Contamination Control Strategy (CCS) and its key elements.

Chapter 3 / Pharmaceutical Quality System (PQS)

New chapter which lists a series of additional PQS requirements specific to sterile manufacturing, which come on top of the requirements in Eudralex Volume 4 Chapter 1 of the GMP guidelines.

Chapter 4 / Premises

This chapter includes requirements from the previous Eudralex Annex 1 chapters “general” and “premises”. It also includes subsections on

- Barrier technologies, replacing the old chapters “isolators” and “RABS”

- Cleanroom and clean air equipment qualification, replacing the old chapter “Clean room and clean air device monitoring”

- Disinfection, replacing the old chapter “sanitation”

In this chapter there are many new and updated requirements, some of which are obvious others may pose a challenge. Noteworthy changes and additions are listed below:

§4.9 … Floor drains in lower grade cleanrooms should be fitted with traps or water seals designed to prevent back flow and should be regularly cleaned, disinfected and maintained

Meaning that companies should be able to demonstrate, e.g. with logbooks that all these required actions take place.

§4.12 and §4.13 include much more detailed requirements regarding airlocks compared to the previous version of annex 1, although most things should be evident and already in place.

§4.15 on airflow patterns (smoke studies) became much more detailed, including description of specific cases such as mouseholes, explicitly requiring such studies in both at rest and operation conditions, and explicitly requiring video recording (something a lot of companies have already worked on in the last years).

§4.16 includes much more detailed requirements regarding differential pressure monitoring compared to the previous version of annex 1, although most things should be evident and already in place.

In the subsection on “Barrier technologies” §4.19 distinguishes “open” and “closed” isolators, and also mentions the use of negative pressure isolators (containment). The remainder of the subsection provides more detailed requirements on background environments, glove systems, and decontamination methods.

In the subsection on“Cleanroom and clean air equipment qualification” there is an important new requirement in §4.25. This paragraph explicitly lists minimum qualification tests to execute and refers to the ISO 14644 “series” instead of only to the first standard in the series. In the previous version of annex 1 only classification and monitoring are mentioned, now there is a new requirement on qualification.

Also in the same section it can be noted that there are slight modifications to the classification limits on particles:

- No more at rest limits specified for 5µ particles in grade A and B

- At rest limits specified for 5µ particles in grade C and D modified to 2930 and 29300

- No more in operation limits specified for 5µ particles in grade A

- In operation limits specified for 5µ particles in grade B and C modified to 2930 and 29300

It also must be said that Eudralex Annex 1 now includes a better definition for “at rest” and “in operation”(§4.29), and is clear on requirements on for example periodic requalification of cleanrooms (§4.32).

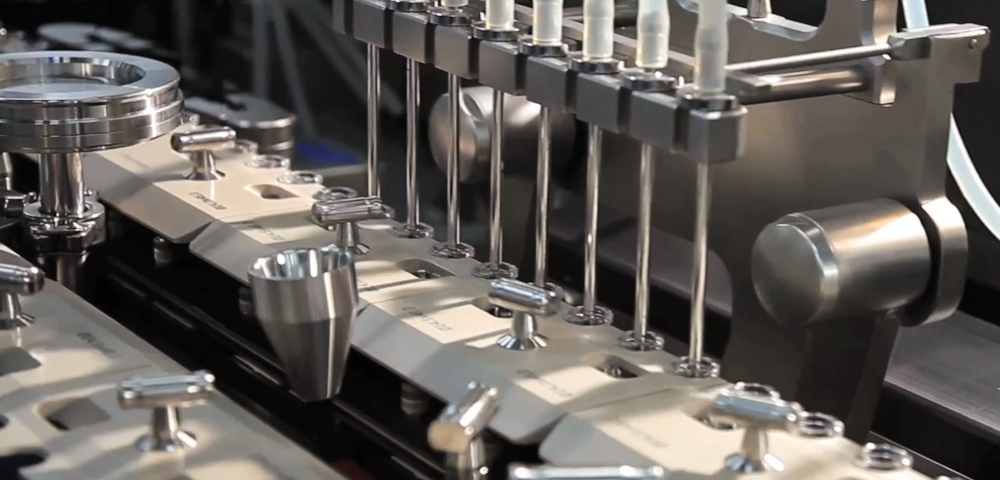

Chapter 5 / Equipment

This chapter in the new Eudralex Annex 1 includes requirements from the old chapters on “equipment” and some requirements from other chapters such as “clean room and clean air device monitoring”. Notable changes and new additions include:

§5.1 A written, detailed description of the equipment design should be available (including process and instrumentation diagrams as appropriate). This should form part of the initial qualification package and be kept up to date.

Companies not having this in place have work to do, also proper management of such files (version, history control and QA approval) should be considered.

§5.6 All equipment such as sterilisers, air handling systems (including air filtration) and water systems should be subject to qualification, monitoring and planned maintenance. Upon completion of maintenance, their return to use should be approved.

One may ask how strict the requirement on AHU’s (Air Handling Units) needing qualification will be interpreted, many companies only consider air handling systems critical from the point of the HEPA filter. This could fuel some interesting discussions.

§5.9 is a more specific on the technical requirements for particle counters compared to the previous version of Eudralex Annex 1

Chapter 6 / Utilities

The chapter on pharmaceutical utilities is an entirely new chapter in Eudralex Annex 1. The previous version hardly mentions utilities.

The chapter defines what “high risk utilities” are, and includes a number of requirements such as

- Monitoring and trending CPP’s, CQA’s

- Maintaining a specification file on each utility, including some very specific content such as drawings, lists of materials, flow direction, components such as valves etc. and this must be kept up to date!

- Requirements on water systems such as importance of turbulent flow, acceptable production methods, monitoring, etc.

- Requirements on steam systems, including clear requirement on physical CQA’s: non-condensable gases, dryness and superheat

- Requirements on gases and vacuum systems

- Requirements on heating, cooling and hydraulic systems

Chapter 7 / Personnel

This chapter in the new Eudralex Annex 1 includes requirements from the old chapter on “personnel”. Some additional aspects are highlighted in the new version, one new requirement that stands out is §7.9 … Electronic devices used in cleanrooms, e.g. mobile phones and tablets, that are supplied by the manufacturer solely for use in the cleanrooms, may be acceptable if suitably designed to permit cleaning and disinfection commensurate with the grade in which they are used. The use and disinfection of such equipment should be included in the CCS.

Chapter 8 / Production and specific technologies

This is the biggest chapter in the new Eudralex Annex 1. It contains many subsections on applicable technologies, with in most cases lengthy and specific technical requirements.

Subsections on sterilization, sterilization by heat, sterilization by moist heat and dry heat provided detailed requirements. New requirements include those in §8.38 and 39 on periodic revalidation, and 8.46 to 49 on handling of sterilized components, materials. Also parametric release is mentioned with reference to Eudralex Volume 4 Annex 17.

The subsection on sterilization by radiation is one of few that became shorter. This is because requirements on radiation sterilization can be found in Eudralex Volume 4 Annex 12 which was published a few years back.

After sterilization comes a subsection on sterilizing filtration “Filter sterilisation of products which cannot be sterilised in their final container”. Also here there are some notable new additions such as specific guidance on a family approach for validation in §8.83 to 85, requirements on filtration of process gases in §8.88 to 90 and requirements on the duration of filter use, campaigning in §8.94 and 95.

There is an entirely new subsection dedicated to Form-Fill-Seal (FFS) and the subsection on Blow-Fill-Seal (BFS) has been upgraded from two paragraphs in the previous version to four full pages.

Also the subsection on Lyophilization has become a full page with specific and technical requirements.

Finally two new subsections have been included on closed systems and single use systems.

Companies which use the technologies listed here above should carefully study technical and other requirements. It can be expected that regulatory inspectors will focus on this as of now.

Chapter 9 / Environmental and process monitoring

This is also an entirely new chapter in the new annex 1, although it includes a lot of requirements which were already in the previous version of Eudralex Annex 1.

There is heavy focus on setting up a monitoring program, and what should be included. Some requirements are new, but most new things are already common practice. Expectations on actions following excursions of alert levels have increased, but this is not unexpected. In §9.15 (table 5) the limits for particle monitoring are listed, there are minor differences with limits used for classification shown in table 1 more at the beginning of the document.

Chapter 10 / Quality control

The final chapter on Quality Control is not an exception, it has become longer and more detailed. But for us there are no major, unexpected changes in this chapter.